|

Excellence in Magnetics and Cost-Effective Manufacturing

Quality

and customer services are the cornerstones upon which TECAL Manufacturing,

LLC of El Paso, Texas, USA, has built its reputation as one of the finest

manufacturers of custom magnetic components in the industry. We are small

enough to be extremely responsive on small-lot, short-run, or prototype

quantities and large enough to handle high-volume, long-run production. TECAL emphasizes quality every step of the way to insure that our output

will meet every standard set by our customers. We chose

the name TECAL in 1983 to express the idea of combining the cost

effectiveness of manufacturing in Texas while utilizing the rapid advances

in technology originating in California. Today, our factory is still in

Texas, but we draw on ideas originating anywhere in the world. reputation as one of the finest

manufacturers of custom magnetic components in the industry. We are small

enough to be extremely responsive on small-lot, short-run, or prototype

quantities and large enough to handle high-volume, long-run production. TECAL emphasizes quality every step of the way to insure that our output

will meet every standard set by our customers. We chose

the name TECAL in 1983 to express the idea of combining the cost

effectiveness of manufacturing in Texas while utilizing the rapid advances

in technology originating in California. Today, our factory is still in

Texas, but we draw on ideas originating anywhere in the world.

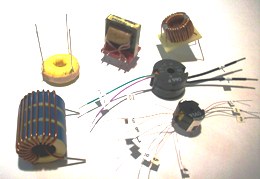

Magnetics means coils and TECAL deals with the full range. Be it

free-standing, intricately shaped air coils, or thousands of turns wound on

a simple plastic bobbin, TECAL can do it. We make coils using wire sizes

compatible with an electrician’s installations (#10 AWG) to those of only 1

or 2 mils (#46 AWG) diameter. We work with insulation systems compatible

with the environment of a motor vehicle or with that of a piece of office

equipment. We package for space flight of for home appliance applications.

A notable

example of our bobbin-wound coil production skills is a two-part coil

combining #40 magnet wire with skeined ends and #21 magnet wire. This coils

is on a 7/8 diameter by 1: long bobbin. Another example is a solenoid coil

on a 5/32” diameter by ½” long bobbin. Both have been made in high volume

over a long period of time.

Toroid

winding for inductors, choke filters, and transformers is another area where

TECAL has expertise. From units machine-wound ith thousands of turns to

hand-wound subminiature units, TECAL does it. We build toroidal coils where

size, material, and turn count are precisely controlled. We also build units

where tight tolerances require that the turn count be adjusted on virtually

every individual part in order to give specific inductance values at a

desired frequency. Toroid

winding for inductors, choke filters, and transformers is another area where

TECAL has expertise. From units machine-wound ith thousands of turns to

hand-wound subminiature units, TECAL does it. We build toroidal coils where

size, material, and turn count are precisely controlled. We also build units

where tight tolerances require that the turn count be adjusted on virtually

every individual part in order to give specific inductance values at a

desired frequency.

Switch-mode or output transformers for high frequency power supplies are a

special challenge. Performance and efficiency often depend on the uniformity

of the wire layering or the way that the wires are “scramble”, as opposed to

being layered.

TECAL has

solved more than a few customer’s problems because we recognize and

appreciate the effects of such details. Examples of our successes are a

transformer used in and energy-saving fluorescent lamp ballast and an EMI

shielded, multiple voltage transformer used in a special-application

computer.

T ECAL also

makes conventional iron core transformers. We have manufactured a range of

such transformers from 100 pound power transformers with multiple secondaries to units that weigh mere grams and must be assembled under

magnification. We manufacture ferrite pot core transformers of all

configurations. ECAL also

makes conventional iron core transformers. We have manufactured a range of

such transformers from 100 pound power transformers with multiple secondaries to units that weigh mere grams and must be assembled under

magnification. We manufacture ferrite pot core transformers of all

configurations.

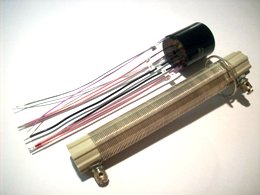

The

recognition that the inductive components in a modern high frequency

switching power supply are second only to the IC control chip itself has led TECAL to manufacture power supplies for widely diverse applications. TECAL

builds a resonant mode, zero current switching power supply that has proven

to be highly reliable for a computer that controls post-production burn-in

and testing a hard disk drive. The TECAL power supply provides 120 watts

with 7 separate output voltages. This extremely compact power supply is just

75% of the volume of power supplies that are considered small by industry

standards. In order to burn-in and test a high (3500 volts) voltage

multiplier, that we manufacture for a military application, TECAL designed

and build a unique power supply with a 1500 volt, nearly perfect square wave

output at 100 kHz. TECAL’s repertoire includes more than miniaturized, solid

state units. We also have the resources to handle high voltage/high current

applications built into standard or custom enclosures. Less complex power

supplies include our line of modular linear AC-to-DC power supplies with up

to three output voltages in a totally encapsulated package.

Additionally, TECAL manufactues, EMI/EMC filters for noise suppression of AC

and DC power lines as well as digital data lines. These filters can be built

into power supplies or provided as free-standing, shielded assemblies. Our

special vacuum molding techniques permit us to encapsulate even sensitive

inductive devices without degrading their performance. Additionally, TECAL manufactues, EMI/EMC filters for noise suppression of AC

and DC power lines as well as digital data lines. These filters can be built

into power supplies or provided as free-standing, shielded assemblies. Our

special vacuum molding techniques permit us to encapsulate even sensitive

inductive devices without degrading their performance.

TECAL

manufactures to either detailed customer-engineered specifications or to the

broadest description of the customer’s problem. If our own management cannot

translate your “need” statement into a product specification, we have access

to specialist who can. By dealing with design and engineering on this basis,

our customers benefit in two ways. TECAL’s overhead stays low; this allows

us to keep our selling prices competitive with many off-shore locations at

all but the highest production volumes. Then too, the engineering talent is

not locked-in to other things that TECAL is doing. You get state-of-the-art

materials and methods to solve the problem at hand. Our work on systems

gives us a better understanding of our components because we recognize them

as the building-blocks that they are.

TECAL

builds several different voltage multiplier networks for laser and low-light

vision enhancement systems. These networks require special care in isolating

high voltages within extremely small volume, and in component selection for

life and reliability. We have on-site facilities for acceptance test, such

as temperature cycling and burn-in (or life) testing under various

environmental conditions.

Quality is

a production-floor concern at TECAL. The combination of our workers’

exceptional pride of workmanship and up-to-date quality management

techniques has enable us to satisfy even the most demanding customers. We

work comfortably with stringent military specifications or highly

competitive commercial requirements. Most of our employees have been with TECAL for several years, thus we operate effectively with low

supervision-to-labor ratios. When needed to support product development in

the “custom magnetics” segment of our business, our technically trained

management can devote the time necessary to insure the successful conclusion

of a project. and up-to-date quality management

techniques has enable us to satisfy even the most demanding customers. We

work comfortably with stringent military specifications or highly

competitive commercial requirements. Most of our employees have been with TECAL for several years, thus we operate effectively with low

supervision-to-labor ratios. When needed to support product development in

the “custom magnetics” segment of our business, our technically trained

management can devote the time necessary to insure the successful conclusion

of a project.

Over the

years much of our business has come by way or referrals; some have come from

customers, others have come from our raw material suppliers, still others

have come from those who provide equipment or services. All of them come

from those who recognize and appreciate TECAL’s attention to detail in every

job that we do.

What can

TECAL Manufacturing, LLC do for you?.... Contact us,

we'll like to earn your business.

|